Home >> News >> How Is Wire Mesh Made?

May. 11, 2022

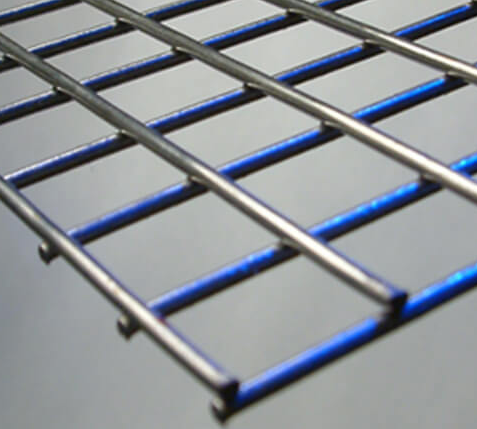

Wire mesh is a common type of metal screen consisting of parallel rows and intersecting columns of wire. Although similar in appearance and their applications, perforated metal sheet and expanded metal sheet are not types of wire mesh. Wire mesh comes in an almost limitless amount of shapes and sizes, and a large variety of materials and metal alloys.

The intersecting wires are typically joined together by welding or weaving – two of the more common forms of wire mesh. The solid wire used is usually made by progressively drawing down a metal in a series of round dies until the desired diameter has been achieved.

There are two common types of mesh:

ㆍWelded Wire Mesh

ㆍWoven Wire Mesh

Welded wire mesh has intersecting rows and columns of parallel wires that are welded together at the intersection. Once the wire has been drawn down to the desired size, it is fed into a machine which welds the multiple rows of wire together at their intersection.

As the mesh is fed through the machine, a parallel line of welds is created simultaneously where the perpendicular lines meet. The next intersection of wires is then fed through the machine to be welded, and this process continues, joining each row of wires together. This machine typically welds the wires using electrical resistance as the source of heat. Although other welding methods could be employed, this is the usually most economical. Once the mesh has reached the desired length, it is cut by a shear, resulting in a sheet of flat and rigid welded wire mesh.

Woven wire mesh has an array of intersecting wires, similar to a woven cloth. Typically, the wires are woven over and under the perpendicular wires producing a stable sheet. This pattern is known as a “Plain Weave Mesh”. For applications that require a more flexible sheet, a “Twill Weave” can be used.

This involves wire that is woven over 2 perpendicular wires, then under the next set of 2 perpendicular wires, and so on. Woven wire mesh has no welds on them. Instead, they are fed into a machine similar to a loom which feeds a straight wire through chosen weave pattern. The wires are then bent to the reverse position, and the next straight wire is fed through the pattern. The machine continues this process until the desired dimensions are reached and the completed wire mesh sheet is then cut to the desired size.

Welded wire mesh and woven wire mesh are used in many different fields. Several uses include:

ㆍFences

ㆍSifters

ㆍGrills

ㆍMachine and equipment safety barricades

ㆍConcrete reinforcement

ㆍShelves

ㆍCages

That’s easy. Aluminum is a highly abundant metal that pairs low density with a high amount of strength. It also offers good malleability, which makes it ideal of weaving into metal screens. It’s also corrosion resistant, which means it stands up well outside and can be used for window screens, fencing, and even outdoor art installations. Aluminum is even easy to recycle, so you can theoretically use it again for a different purpose.

We are an aluminium expanded mesh bunnings supplier. If you are interested in our products, please contact us now!

Previous: None